The DNP3 protocol — short for Distributed Network Protocol version 3 — is a robust and reliable communication standard primarily used in SCADA (Supervisory Control and Data Acquisition) systems. It was designed to enable efficient, secure, and interoperable communication between control systems (master stations) and remote field devices such as RTUs (Remote Terminal Units) and IEDs (Intelligent Electronic Devices) across industries like electric utilities, oil and gas, and water management.

Table of Contents

Background and Development

Originally developed by Harris Controls Division in the early 1990s, DNP3 was intended for the electric utility industry. In 1993, the protocol was released to the public domain under the DNP3 User Group, which now maintains and develops the standard.

DNP3 shares its roots with the IEC 60870-5 protocol but evolved independently, offering broader applications across multiple industries beyond power systems.

The DNP3 protocol’s design philosophy centers on reliability, determinism, and efficiency—qualities essential for real-time monitoring and control over potentially unreliable communication networks.

Purpose and Function

DNP3 was specifically engineered for SCADA communication, allowing the exchange of status, event, and control information between master stations and distributed devices. It supports small, time-critical messages and ensures they are transmitted in the correct sequence — unlike general-purpose protocols such as FTP or TCP/IP that handle large, non-deterministic data transfers.

Key roles of DNP3 include:

- Collecting data from field devices (analog/digital inputs, counters)

- Transmitting control commands to actuators or relays

- Timestamping events for accurate sequence of events (SOE) recording

- Maintaining system integrity under noisy or unstable communication conditions

Core Features of DNP3

The DNP3 protocol offers several technical and operational advantages:

- Open standard: Freely available and supported by numerous manufacturers.

- Interoperability: Allows equipment from different vendors to communicate seamlessly.

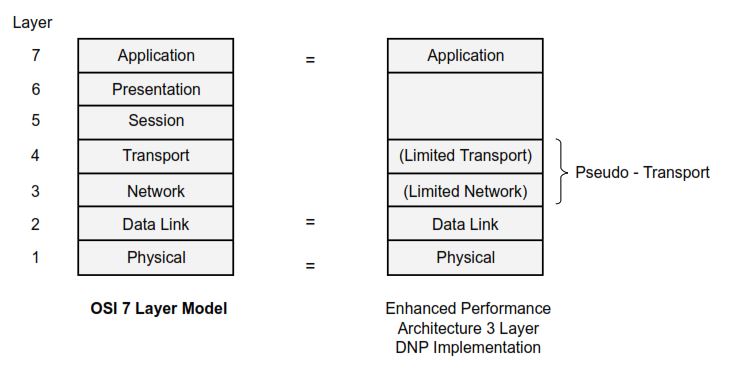

- Layered architecture: Based on the IEC Enhanced Performance Architecture (EPA) model, simplifying communication into three layers — physical, data link, and application.

- Reliable communication: Uses error checking (CRC), confirmations, and retries.

- Event-driven reporting: Supports report by exception, where outstations send updates only when data changes.

- Multiple topologies: Operates in master–slave, peer-to-peer, and multiple-master configurations.

- Time synchronization: Ensures accurate timestamping for events across devices.

- Scalability: Addresses up to 65,000+ devices on a single link.

DNP3 System Architecture

The DNP3 communication model typically involves:

- Master Station (Control Center) – The supervisory node that initiates commands and collects data.

- Outstations (RTUs or IEDs) – Field devices that respond to master requests or send unsolicited reports.

- Communication Media – The physical or network layer carrying the protocol (serial, TCP/IP, or radio links).

DNP3 supports both polled operation (master requests data) and quiescent operation (report by exception), where devices send updates only when significant changes occur. This dual-mode capability conserves bandwidth while ensuring timely event reporting.

DNP3 Message Structure

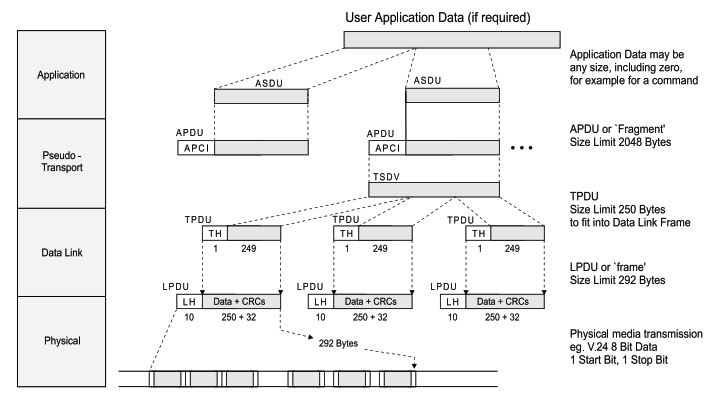

DNP3 organizes communication into multiple layers to ensure reliable message delivery:

- Physical Layer: Defines electrical and communication standards (e.g., RS-232, Ethernet, or radio).

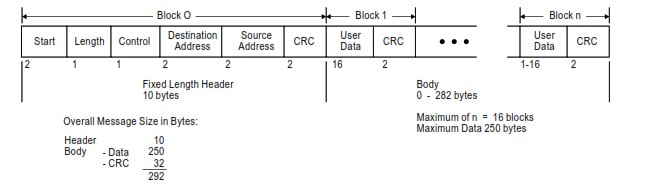

- Data Link Layer: Manages reliable delivery using frame headers, control bytes, addressing, and error checking (CRC).

- Pseudo-Transport Layer: Splits large messages into smaller fragments for transmission and reassembly.

- Application Layer: Contains actual SCADA commands, data, and responses. Messages here can be requests, responses, or unsolicited responses.

Each complete message is encapsulated as an Application Protocol Data Unit (APDU), which is then broken into smaller transport and link-layer frames.

This layered encapsulation guarantees end-to-end data integrity and efficient handling of real-time control messages.

Benefits of DNP3

The DNP3 protocol standard provides both immediate and long-term operational advantages:

Immediate Benefits

- True multi-vendor interoperability

- Reduced need for protocol translators

- Simplified maintenance and integration

- Lower software and training costs

- Faster system deployment and testing

Long-Term Benefits

- Easy system expansion and modernization

- Longer product lifecycle

- Support for value-added features from different vendors

- Ongoing technical evolution through the DNP3 User Group

Why DNP3 is Widely Used

Industries adopt DNP3 protocol because it strikes a balance between performance, reliability, and openness. It provides:

- Efficient real-time communication even over low-bandwidth or noisy links.

- Secure, deterministic data flow critical for automation and protection systems.

- Long-term vendor support and standardization, ensuring compatibility across generations of equipment.

Conclusion

The DNP3 protocol is a cornerstone of modern industrial communication and SCADA systems. By providing a standardized, open, and reliable framework, it enables organizations in power, water, oil, and gas sectors to achieve seamless automation, data integrity, and interoperability across diverse hardware and software platforms.

In short, DNP3 is not just a communication protocol—it’s the backbone of efficient, secure, and scalable industrial control.