Industrial Ethernet networks form the backbone of modern SCADA, substation automation, manufacturing, and process control systems. Unlike traditional office IT networks, industrial networks must provide high availability, predictable behavior, and fast recovery from failures. Even short communication interruptions can lead to production losses, control instability, or safety risks.

To meet these requirements, redundancy is commonly built into industrial Ethernet topologies. However, redundancy introduces a serious challenge: Ethernet loops, which can cause broadcast storms and network collapse if not properly controlled.

Rapid Spanning Tree Protocol (RSTP) is one of the most widely used protocols to manage redundancy and prevent loops in industrial Ethernet networks. This article provides a comprehensive, engineering-focused explanation of RSTP, how it evolved, how it works, and how it is applied in real-world SCADA and industrial environments.

Table of Contents

Evolution from STP to RSTP

Original Spanning Tree Protocol (STP)

The original Spanning Tree Protocol (STP) was defined in IEEE 802.1D. It was designed to prevent Ethernet loops by creating a loop-free logical topology while allowing physical redundancy.

However, STP relies heavily on timer-based mechanisms, resulting in slow recovery times:

- Typical STP convergence time: 30–50 seconds

While acceptable in office networks, this delay is unacceptable in industrial systems, where communication loss of even a few seconds can disrupt control processes.

Introduction of Rapid Spanning Tree Protocol

To address these limitations, Rapid Spanning Tree Protocol (RSTP) was introduced as IEEE 802.1w.

Key milestones:

- 2004: RSTP replaced STP within the IEEE 802.1D standard

- 2011: All RSTP functionality was fully integrated into IEEE 802.1Q

RSTP retains the core loop-prevention logic of STP while dramatically improving reconvergence speed.

- Typical RSTP convergence time: ~1 second

This improvement made RSTP suitable for many industrial Ethernet applications.

Why RSTP Matters in Industrial Ethernet Networks

Industrial networks differ from IT networks in several critical ways:

Industrial Network Requirements

- Deterministic communication

- High availability

- Fast fault recovery

- Stable topology behavior

- Minimal operator intervention

A slow reconvergence event can result in:

- Loss of PLC or IED communication

- Frozen HMI displays

- Delayed alarms and events

- Control logic interruptions

- Production downtime

RSTP was designed to meet these needs by enabling rapid reconfiguration after topology changes, making it a practical redundancy solution for SCADA and OT networks.

How RSTP Works – Core Concepts

RSTP operates at Layer 2 and prevents loops by controlling which Ethernet ports are allowed to forward traffic.

Root Bridge Election

All managed switches participating in RSTP exchange information and elect one switch as the root bridge.

- The root bridge becomes the reference point for the entire topology

- All active ports on the root bridge are placed in the forwarding state

Non-Root Switch Behavior

All other switches become non-root switches. Each non-root switch:

- Calculates the best path to the root bridge

- Selects the port with the lowest path cost as its root port

- Places redundant ports into a blocking (discarding) state

This ensures that only one active logical path exists between any two points in the network.

RSTP Port Roles and States

RSTP simplifies and improves the original STP port model.

Port Roles

- Root Port – Best path toward the root bridge

- Designated Port – Forwarding port for a network segment

- Alternate Port – Backup path to the root

- Backup Port – Redundant port on the same segment

Port States

- Discarding – Not forwarding traffic

- Learning – Building MAC address table

- Forwarding – Fully operational

RSTP eliminates unnecessary listening delays and uses rapid handshaking between switches to transition ports quickly.

RSTP Convergence in Industrial Environments

One of the most important advantages of RSTP is its fast convergence.

- STP: Up to 50 seconds

- RSTP: Typically 1 second or less

In industrial Ethernet networks, this means:

- Faster restoration of SCADA communication

- Reduced alarm flooding

- Improved system stability

- Lower risk of process interruption

Actual convergence time depends on:

- Switch hardware performance

- Network size

- Configuration parameters

- Link detection speed

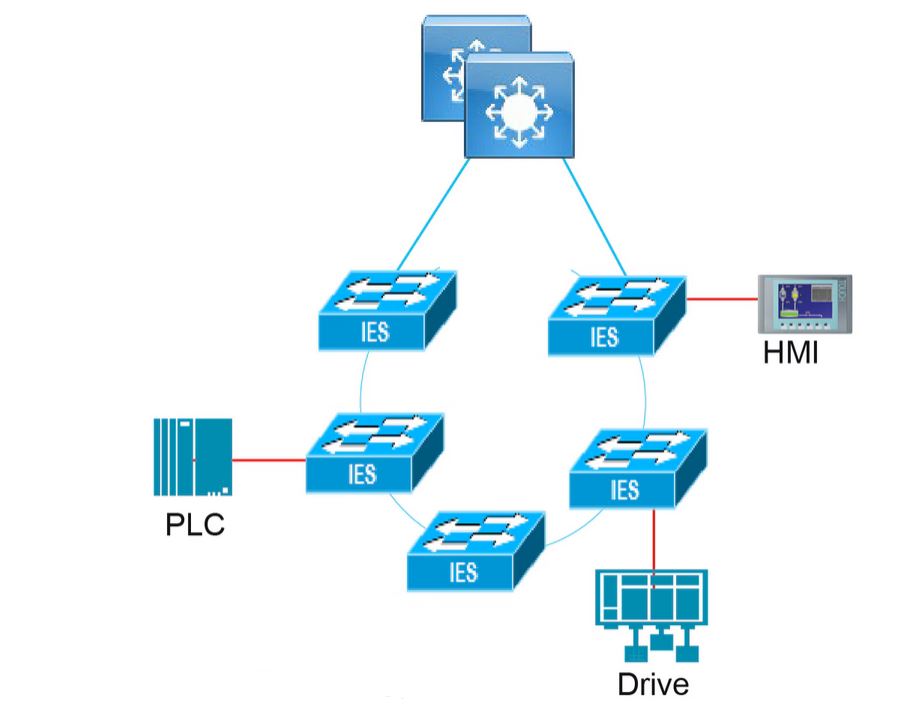

RSTP and Industrial Ethernet Topologies

Ring Topologies

Ring topologies are very common in industrial environments due to:

- Simple cabling

- High resilience

- Cost efficiency

In an RSTP-protected ring:

- One link is blocked during normal operation

- If a link fails, RSTP unblocks the alternate path

- Communication continues around the ring with minimal delay

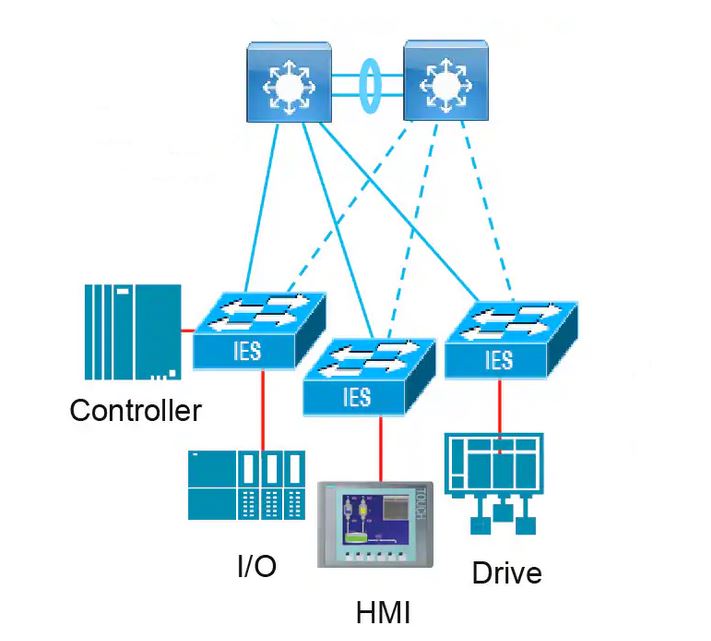

Redundant Star and Partial Mesh

RSTP is also widely used in:

- Redundant uplinks to core switches

- Substation Ethernet backbones

- SCADA aggregation networks

RSTP ensures loop-free operation while keeping redundant paths available for failover.

Role of Managed Ethernet Switches

RSTP requires managed Ethernet switches.

Key points:

- RSTP logic runs only on switches

- End devices such as PLCs, IEDs, relays, and HMIs do not participate in RSTP

- There are no RSTP settings on field devices

Managed switches:

- Elect the root bridge

- Control port roles and states

- Detect link failures

- Restore traffic paths automatically

Using unmanaged switches in an RSTP topology can break loop protection and must be avoided.

Failure Detection and Recovery

When a link or switch fails in an RSTP network:

- The switch detects loss of link

- RSTP recalculates the topology

- A previously blocked port transitions to forwarding

- Traffic is rerouted through the alternate path

The resulting switchover delay is typically short and predictable, making RSTP suitable for many industrial control applications.

When RSTP Is a Good Choice

RSTP is well suited when:

- A brief switchover delay is acceptable

- Multi-vendor compatibility is required

- Standard managed switches are preferred

- Network simplicity is important

Common use cases include:

- SCADA communication networks

- Factory automation systems

- Utility and substation networks

- Industrial control backbones

Limitations of RSTP in Industrial Systems

Although RSTP is fast, it is not seamless.

RSTP may not be sufficient when:

- Zero packet loss is required

- Protection relaying traffic is time-critical

- Sub-millisecond recovery is mandatory

In such cases, specialized industrial redundancy protocols may be required.

Best Practices for RSTP in Industrial Ethernet

- Manually configure the root bridge

- Use high-quality managed industrial switches

- Avoid mixing IT and OT default configurations

- Test failure scenarios during commissioning

- Document topology and switch roles

- Keep firmware versions consistent

Proper planning and testing are essential to ensure predictable RSTP behavior.

RSTP Compared to Other Industrial Redundancy Protocols

| Protocol | Typical Recovery Time | Notes |

|---|---|---|

| STP | 30–50 s | Legacy, slow |

| RSTP | ~1 s | Widely supported |

| MRP | <200 ms | Ring-specific |

| PRP / HSR | 0 ms | Seamless redundancy |

RSTP remains popular because it provides a balance of speed, simplicity, and compatibility.

Conclusion

Rapid Spanning Tree Protocol (RSTP) is a critical technology for industrial Ethernet redundancy. By significantly reducing convergence time compared to traditional STP, RSTP enables reliable and resilient communication in SCADA, automation, and OT networks.

While not suitable for applications requiring seamless, zero-loss recovery, RSTP remains a foundational protocol for many industrial environments due to its simplicity, wide support, and predictable behavior.

When designed and configured correctly, RSTP provides an effective and proven solution for maintaining availability in industrial Ethernet networks.