Industrial networks depend heavily on reliable and continuous communication. Protection devices, SCADA gateways, and automation controllers must exchange information with strict timing and without interruption. Even a brief communication loss can cause protective functions to misoperate or lose visibility of the grid.

To avoid this, industrial networks rely on seamless Ethernet redundancy methods that guarantee zero-time recovery. The two most widely used methods are Parallel Redundancy Protocol (PRP) and High-Availability Seamless Redundancy (HSR).

Although both technologies offer the same guarantee—continuous communication even when part of the network fails—they use different architectures to achieve it. Each approach has strengths and limitations, making them suitable for different layers of a substation. In many modern systems, engineers combine PRP and HSR in a hybrid architecture, taking advantage of the best features of both.

Understanding how these two redundancy methods differ and how they can be interconnected is essential for designing reliable IEC 61850 networks.

Table of Contents

How PRP Works

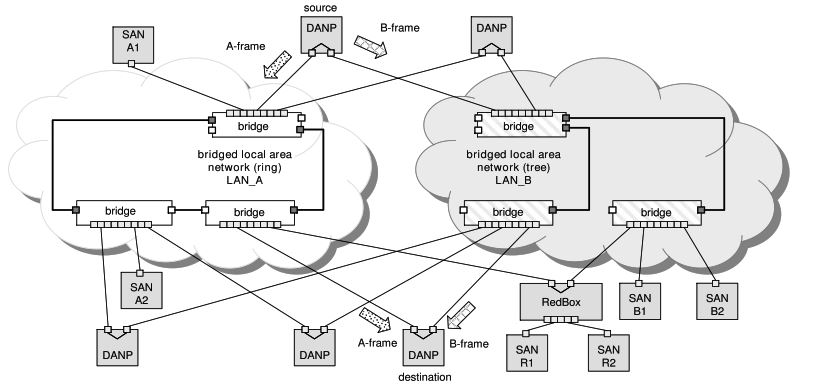

PRP provides redundancy by using two completely independent networks, usually referred to as LAN A and LAN B. A device supporting PRP sends the same Ethernet frame into both networks at the same time. The destination receives two copies but keeps only the first one. If one network fails, the other continues delivering data instantly because it has always been active.

This design has several advantages. It requires no switchover time, no recalculation, and no reconfiguration when failures occur. Because the two networks are independent, they can be built using standard Ethernet switches and may even follow different physical paths. This greatly reduces the chance of a common failure taking down both networks at once. PRP therefore provides excellent robustness, especially in environments where the communication infrastructure is centralized or connected to control-room systems.

PRP devices typically operate like ordinary hosts. They do not forward frames for other devices. Their role is simply to send duplicate frames and remove duplicates on reception. Because of this, PRP is well suited for station bus architectures, gateways, protection relays at higher levels, servers, SCADA systems, and other equipment located near redundant network switches. It integrates easily with existing Ethernet infrastructure and does not depend on specialized switching hardware.

How HSR Works

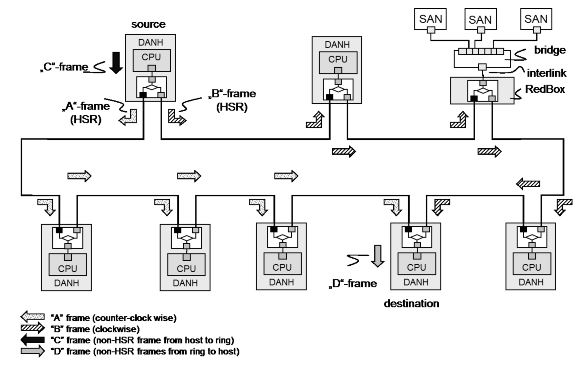

While PRP relies on two networks, HSR achieves redundancy within a single ring. Devices participating in an HSR ring forward frames for one another. When an HSR device sends a frame, it immediately transmits two copies, one in each direction around the ring. Every device receives both copies, processes the first one that arrives, and discards the second. This behavior ensures that a single break in the ring does not interrupt communication. The remaining direction continues delivering frames with no interruption.

Because all devices act as forwarding nodes, the ring maintains redundancy even without special switches. This makes HSR ideal for distributed equipment such as merging units, bay-level relays, and process bus devices located across the switchyard. The physical layout of the process bus often naturally forms loops between equipment, making HSR easier to implement without long cable runs back to the control room.

HSR does, however, introduce more traffic because every frame is duplicated and forwarded. As the number of nodes grows, forwarding delays accumulate and traffic increases. For this reason, HSR works best for small to medium-sized rings, such as bay-level networks that handle Sampled Values and GOOSE messages. Its deterministic behavior and zero-time recovery make it a strong choice for real-time process-level systems.

PRP and HSR Compared

PRP and HSR both provide seamless redundancy, but they target different types of architectures. PRP prefers independence: two networks running in parallel, each capable of carrying all traffic. HSR prefers cooperation: a ring of devices that continuously circulate traffic among themselves.

In PRP, redundancy depends on two isolated paths. If one fails, the frames arriving on the remaining path are already sufficient to keep communication running. In HSR, redundancy depends on a loop. If the loop is broken at one point, traffic simply flows the other way.

PRP tends to scale well in large distributed networks because the cost of redundancy is simply the cost of duplicating the infrastructure. HSR tends to scale well within local segments because it uses a single network and the devices themselves handle forwarding. PRP uses standard switches, while HSR requires HSR-capable nodes to maintain the ring. PRP fits central equipment; HSR fits distributed field equipment.

In protection applications, both methods guarantee that GOOSE and Sampled Values can continue flowing without interruption. In SCADA environments, PRP is more commonly used because servers and gateways typically sit behind redundant switches. In process bus environments, HSR is more common because equipment is often arranged physically in a ring around a bay.

Why Substations Often Use Both

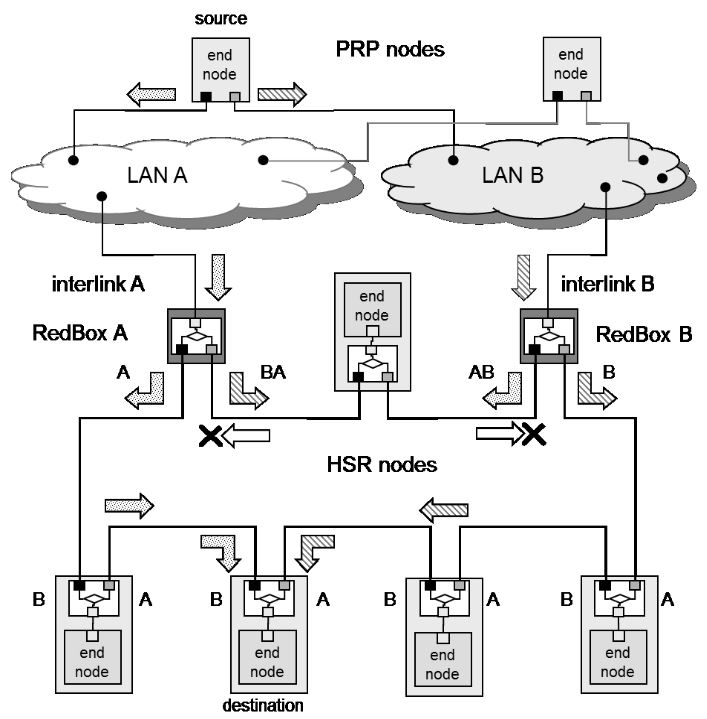

In practice, most digital substations do not rely exclusively on one method. Instead, they use a combination of PRP and HSR. This reflects the fact that different parts of the substation have different physical layouts and performance needs.

Process bus networks often use HSR rings. Each bay may have its own ring connecting merging units, protection IEDs, sensors, and actuators. This approach reduces cabling and provides seamless redundancy at the process level.

Station bus networks often use PRP. At this level, SCADA servers, gateway devices, the control center interface, and other central systems connect to two independent LANs. This ensures high resilience without requiring these devices to forward traffic or participate in ring logic.

These two domains must still communicate with each other. HSR devices must exchange data with PRP-capable devices, and both must interact with standard Ethernet equipment used in engineering and monitoring. This is where interconnection devices enter the picture.

Connecting PRP and HSR Networks

PRP and HSR can operate together through special devices known as RedBoxes. A RedBox acts as the translator between different redundancy domains. It appears as a single HSR node within the ring but also connects to the two PRP networks or to a standard Ethernet network.

When a RedBox receives a frame from a PRP device, it performs several actions. It removes the PRP redundancy information, inserts an HSR header, duplicates the frame, and injects it into the ring. When frames arrive from the HSR ring, the RedBox removes duplicates and forwards a single copy to the PRP network or to the standard Ethernet side. This ensures that devices outside the ring behave normally and remain unaware of the HSR ring’s internal redundancy.

Hybrid designs often use multiple RedBoxes to connect several HSR rings to the PRP-based station bus. For example, in electrical substation, each bay-level HSR ring may be linked through a RedBox to the redundant station bus networks. The merging units and protection IEDs in each bay then gain access to SCADA systems, time servers, or control room applications without losing the benefits of their local redundancy.

In some architectures, multiple rings are interconnected while also being linked to PRP networks. In such cases, more advanced interconnection units may be used to prevent loops and ensure that redundancy remains seamless across all domains.

Choosing Between PRP and HSR

Selecting between PRP and HSR depends on the structure of the substation and the role of each device. When equipment is spread along a bay or line and lends itself to a continuous loop, HSR is usually the better choice. When equipment is concentrated in central areas or needs to integrate with standard Ethernet switches, PRP is typically preferred.

The choice is rarely absolute. Most substations use both, simply in different areas. The process bus benefits from the natural ring-like structure of HSR, while the station bus benefits from the independence and flexibility of PRP. Hybrid designs give engineers the freedom to select the right technology for each part of the network without forcing incompatible architectures.

Conclusion

PRP and HSR are both powerful technologies that ensure seamless redundancy in IEC 61850 industrial networks. They achieve the same goal but through different designs. PRP uses two independent networks, making it ideal for centralized architectures and high-level systems. HSR uses a single ring of forwarding devices, making it ideal for process bus applications where equipment is physically distributed.

The combination of the two—connected through RedBoxes or similar devices—creates a flexible and fault-tolerant architecture. Each domain benefits from the redundancy method most suitable to its layout. Together, they form a unified communication system capable of supporting the most demanding protection and automation functions without a single point of failure.