Modbus is one of the most widely used communication protocols in industrial automation and control systems. Originally designed for serial networks, Modbus evolved to work seamlessly over Ethernet and IP networks, creating two common variants — Modbus RTU and Modbus TCP/IP.

Although both use the same core data model and function codes, they differ in frame structure, transmission medium, and protocol layers.

Table of Contents

Modbus RTU vs Modbus TCP/IP Overview

Modbus RTU and Modbus TCP/IP are two communication variants of the same Modbus protocol family. They share an identical application layer—meaning the same function codes and data model—but differ in how they transport and frame messages between devices.

Modbus RTU is the serial-line version of the protocol, designed for communication over RS-232 or RS-485 links. It sends data in compact binary frames and relies on timing gaps between messages to separate frames.

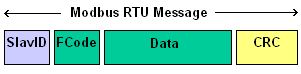

Each frame contains a Slave ID, Function Code, Data field, and a CRC (Cyclic Redundancy Check) for error detection. Because it operates over serial lines, Modbus RTU supports limited data rates (typically up to 115.2 kbps) and a restricted number of devices—usually up to 32 nodes per segment.

Modbus TCP/IP, by contrast, is the Ethernet-based implementation of Modbus.

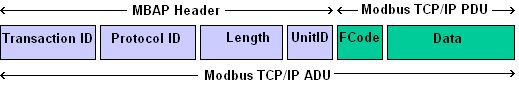

It encapsulates the same Modbus commands inside TCP/IP packets and communicates over standard Ethernet infrastructure, usually via port 502. In this version, timing gaps and CRC checks are no longer needed—TCP handles delivery, sequencing, and error control.

Each Modbus TCP/IP message begins with an MBAP (Modbus Application Protocol) header, which includes a Transaction ID, Protocol ID, Length, and Unit ID, followed by the Function Code and Data fields identical to those in RTU.

In practice:

- Modbus RTU is ideal for local, low-cost serial networks connecting field devices such as meters, sensors, or controllers over short distances.

- Modbus TCP/IP is suited for modern Ethernet networks, providing higher speed, scalability, and easy integration with IT systems, cloud platforms, and industrial Ethernet infrastructure.

Despite the differences in transport layers, both RTU and TCP/IP maintain complete functional compatibility, allowing engineers to bridge between them easily using Modbus gateways.

Modbus RTU Frame Structure

Modbus RTU (Remote Terminal Unit) is the traditional serial communication format used over RS-232 or RS-485 links. It’s compact, efficient, and widely used in field-level control where simplicity and reliability matter more than speed.

Modbus RTU transmits data in binary format and uses precise timing gaps to separate messages. Every frame contains a fixed structure: the Slave ID, Function Code, and Data, followed by a CRC-16 checksum that verifies message integrity.

Frame Structure

| Field | Size (bytes) | Description |

|---|---|---|

| Slave ID | 1 | Address of the device (1–247). Identifies which slave the master is communicating with. |

| Function Code (FCode) | 1 | Defines the action (e.g., read, write, diagnostic). |

| Data | Variable | Contains register addresses, values, or coil data depending on the function code. |

| CRC | 2 | 16-bit Cyclic Redundancy Check used for error detection. |

Frame Timing

Unlike TCP/IP systems, Modbus RTU relies on silent intervals to indicate the end of a frame:

- 3.5 character times of silence before a new frame starts.

- 1.5 character times of silence between characters within a frame.

If this timing rule is violated, devices may misinterpret frames or trigger CRC errors.

Because of this, baud rate configuration must be identical on all devices within the same RS-485 network.

Example Modbus RTU Request

Example: A master requests to read 10 holding registers starting from address 40001 on Slave 1.

Request Frame (Hex):

01 03 00 00 00 0A C5 CDField Breakdown:

| Field | Hex Value | Meaning |

|---|---|---|

| Slave ID | 01 | Address of target device |

| Function Code | 03 | Read Holding Registers |

| Starting Address | 00 00 | Register 40001 |

| Quantity of Registers | 00 0A | 10 registers |

| CRC | C5 CD | Error check (LSB + MSB) |

Response example (from Slave 1):

01 03 14 00 64 00 65 00 66 00 67 00 68 00 69 00 6A 00 6B 00 6C 00 6D 00 6E 4C D9

Here, 10 register values are returned (20 bytes of data).

Function Codes in Modbus RTU

Modbus RTU supports a wide range of function codes used for reading, writing, and controlling data.

Below are the most commonly implemented ones:

| Function Code | Operation | Description |

|---|---|---|

| 01 | Read Coils | Reads discrete outputs (ON/OFF states). |

| 02 | Read Discrete Inputs | Reads digital input states. |

| 03 | Read Holding Registers | Reads analog registers (4xxxx). |

| 04 | Read Input Registers | Reads analog input values (3xxxx). |

| 05 | Write Single Coil | Forces one digital output ON/OFF. |

| 06 | Write Single Register | Writes one analog register. |

| 15 (0x0F) | Write Multiple Coils | Writes multiple discrete outputs. |

| 16 (0x10) | Write Multiple Registers | Writes multiple analog registers. |

Advantages of Modbus RTU

- Simple and well-established for industrial devices.

- Low bandwidth requirements.

- Works reliably over long distances (up to 1200 m on RS-485).

- Excellent for legacy equipment still using serial interfaces.

Limitations

- Limited node count per RS-485 segment (≈32 without repeaters).

- Sensitive to noise and baud rate mismatches.

- Requires manual addressing and tight timing configuration.

Modbus TCP/IP Frame Structure

Modbus TCP/IP is the Ethernet-based version of the Modbus protocol. It transmits standard Modbus messages within TCP/IP packets over an Ethernet network, typically using TCP port 502.

Unlike Modbus RTU, it does not require special timing or CRC checks because TCP/IP inherently guarantees data delivery, order, and integrity. This makes Modbus TCP/IP ideal for high-speed industrial communication, SCADA systems, and large-scale automation networks.

Frame Structure

A Modbus TCP/IP message consists of two main parts:

- MBAP Header (Modbus Application Protocol Header) – 7 bytes

- PDU (Protocol Data Unit) – Function Code + Data

| Field | Size (bytes) | Description |

|---|---|---|

| Transaction ID | 2 | Identifies request/response pairs between client and server. |

| Protocol ID | 2 | Always 0x0000 for Modbus TCP/IP. |

| Length | 2 | Number of bytes following (Unit ID + Function Code + Data). |

| Unit ID | 1 | Slave address for bridging to RTU devices; often set to 0x01 or 0xFF. |

| Function Code | 1 | Specifies the operation (e.g., read, write). |

| Data | Variable | Contains register addresses, values, or coil data depending on the function. |

Example Modbus TCP/IP Request

Example: A client requests to read 10 holding registers starting from address 40001.

Request Frame (Hex):

00 01 00 00 00 06 01 03 00 00 00 0A

Field Breakdown:

| Field | Hex Value | Meaning |

|---|---|---|

| Transaction ID | 00 01 | Request #1 |

| Protocol ID | 00 00 | Modbus protocol |

| Length | 00 06 | 6 bytes follow |

| Unit ID | 01 | Slave (or RTU bridge) address |

| Function Code | 03 | Read Holding Registers |

| Starting Address | 00 00 | Register 40001 |

| Quantity of Registers | 00 0A | 10 registers |

Response Example:

00 01 00 00 00 17 01 03 14 00 64 00 65 00 66 00 67 00 68 00 69 00 6A 00 6B 00 6C 00 6D 00 6E

Here, the server returns 10 register values (20 bytes of data) within the Modbus TCP frame.

MBAP Header Details

The MBAP Header allows Modbus TCP/IP to operate efficiently over TCP connections:

- Transaction ID: Used to match multiple outstanding requests with their responses.

- Protocol ID: Always zero for Modbus, enabling protocol multiplexing if needed.

- Length: Defines the message size for proper segmentation.

- Unit ID: Maintains backward compatibility with Modbus RTU gateways.

Because TCP handles sequencing and error control, the CRC field used in RTU is no longer needed.

Function Codes in Modbus TCP/IP

The same Modbus function codes apply to TCP/IP and RTU, making them interoperable at the application layer.

| Function Code | Operation | Description |

|---|---|---|

| 01 | Read Coils | Read discrete outputs |

| 02 | Read Discrete Inputs | Read digital input states |

| 03 | Read Holding Registers | Read analog holding registers |

| 04 | Read Input Registers | Read analog input values |

| 05 | Write Single Coil | Write one digital output |

| 06 | Write Single Register | Write one analog register |

| 15 (0x0F) | Write Multiple Coils | Write multiple digital outputs |

| 16 (0x10) | Write Multiple Registers | Write multiple analog registers |

Advantages of Modbus TCP/IP

- Higher speed: Operates over Ethernet at 10/100 Mbps or more.

- Scalable: Supports many devices and concurrent connections.

- Reliable: Built-in error handling and retransmission via TCP.

- Flexible: Works across LAN, WAN, and VPN networks.

- Compatible: Easily integrates with RTU systems via gateways.

Limitations

- Requires network configuration and IP management.

- Slightly higher overhead compared to RTU.

- Depends on reliable Ethernet infrastructure.

Modbus RTU vs Modbus TCP/IP Summary and Migration Guide

Both Modbus RTU and Modbus TCP/IP remain essential in industrial communication — each suited to specific infrastructure and performance needs. While Modbus RTU is optimized for serial communication in localized field networks, Modbus TCP/IP extends the same protocol into the Ethernet domain, providing better scalability, speed, and flexibility.

Key Comparison Summary

| Aspect | Modbus RTU | Modbus TCP/IP |

|---|---|---|

| Transport Medium | Serial (RS-232 / RS-485) | Ethernet (TCP/IP) |

| Topology | Point-to-point or multidrop | Client–Server (Master–Slave) |

| Port / Channel | Serial port (COM) | TCP Port 502 |

| Frame Delimitation | Timing gaps (3.5 chars) | TCP length field |

| Error Checking | CRC-16 checksum | TCP/IP checksum |

| Header Type | None (raw frame) | MBAP header (7 bytes) |

| Data Integrity | Checked by CRC | Ensured by TCP layer |

| Max Devices | Up to 32 per segment | Virtually unlimited |

| Speed | Up to 115.2 kbps | 10 / 100 Mbps or higher |

| Addressing | Slave ID (1–247) | IP Address + Unit ID |

| Physical Range | Typically <1.2 km (RS-485) | LAN / WAN / VPN capable |

| Scalability | Limited | Very high |

| Ease of Integration | Simple and low-cost | Plug-and-play over Ethernet |

| Ideal Use Case | Local serial networks with legacy devices | Modern SCADA, PLC, and IoT integration |

Compatibility and Interoperability

The greatest advantage of the Modbus family is that RTU and TCP/IP share the same application layer.

This means all function codes (such as Read Coils, Read Registers, Write Registers) are identical in both implementations.

The only difference is how data is framed and transported:

- In RTU, the frame is wrapped with a CRC and defined by serial timing.

- In TCP/IP, the same data is encapsulated inside a TCP segment with an MBAP header.

Because of this, devices can interoperate easily through a Modbus gateway that translates between serial and Ethernet formats.

Migration from Modbus RTU to Modbus TCP/IP

Transitioning from Modbus RTU to TCP/IP is straightforward, thanks to shared structure and function codes.

Typical migration steps include:

- Install Modbus TCP/RTU Gateways:

These devices connect legacy serial Modbus RTU equipment to Ethernet networks. The gateway converts Modbus RTU frames into Modbus TCP/IP packets transparently. - Map Slave IDs to Unit IDs:

In Modbus TCP/IP, each RTU device is represented by a unique Unit ID, while its IP address identifies the gateway or Ethernet node. - Configure Master (Client) Software:

Update the master system or SCADA application to connect over port 502 instead of COM ports. Function codes, register maps, and data formats remain unchanged. - Validate Timing and Performance:

Because TCP/IP introduces latency variability, ensure the new network infrastructure supports your real-time performance needs.

Benefits of Migration

- Unified Communication: Ethernet connectivity across PLCs, RTUs, HMIs, and servers.

- Higher Bandwidth: Supports real-time data logging and historian systems.

- Remote Access: Monitor and control equipment over LAN, WAN, or VPN.

- Future-Proofing: Enables integration with modern IIoT and Industry 4.0 platforms.

- Reduced Maintenance: No physical serial cabling limits or termination resistors to manage.

Migration Considerations

Before migrating, review:

- Device Compatibility: Ensure all Modbus devices support identical function codes and data formats.

- Network Security: TCP/IP exposes devices to network-level threats — use firewalls, VLANs, or VPNs.

- Gateway Configuration: Assign unique Unit IDs to avoid address conflicts.

- Performance Testing: Validate message latency under normal and peak load conditions.

Frequently Asked Questions (FAQ)

What is the difference between Modbus RTU and Modbus TCP/IP?

The main difference lies in the transport layer. Modbus RTU works over serial lines (RS-232/RS-485) and uses a CRC checksum for error checking, while Modbus TCP/IP runs over Ethernet using TCP/IP, encapsulating Modbus frames with an MBAP header instead of CRC. Function codes and data structures remain the same in both versions.

Can I use Modbus RTU devices on an Ethernet network?

Yes, but you’ll need a Modbus gateway or serial-to-Ethernet converter. These devices allow Modbus RTU slaves to communicate with Ethernet-based Modbus TCP/IP masters by encapsulating serial data into TCP frames — preserving all function codes and data structures.

What port does Modbus TCP/IP use?

Modbus TCP/IP uses TCP port 502 for all client–server (master–slave) communication. This is a well-known port officially registered with the IANA (Internet Assigned Numbers Authority). Firewalls and routers should allow inbound and outbound traffic on this port to enable Modbus TCP/IP communication.

Is Modbus TCP faster than Modbus RTU?

Yes — Modbus TCP/IP is significantly faster than Modbus RTU. While Modbus RTU over RS-485 typically operates between 9.6 kbps and 115.2 kbps, Modbus TCP/IP runs on Ethernet networks at 10/100 Mbps or higher. It also supports parallel transactions, making it ideal for high-performance SCADA systems.

Conclusion

Modbus RTU remains reliable and cost-effective for serial-based systems, especially in small-scale or legacy installations. Modbus TCP/IP, however, provides the scalability, speed, and interoperability required for modern Ethernet-based SCADA and automation systems.

Because both share the same logic and function codes, they can coexist — enabling hybrid architectures where gateways bridge field serial devices with Ethernet-based controllers and data servers.

💡 In short: Modbus RTU built the foundation; Modbus TCP/IP connects it to the future of industrial communication.

Try It Yourself — Decode Modbus Frames Instantly

Want to see how Modbus RTU and Modbus TCP/IP frames actually look and behave?

Use our free online Modbus Frame Decoder & Encoder Tool to analyze, validate, and convert Modbus messages in real time.

Try it now: Modbus Frame Decoder & Encoder Tool