The IEC 60870-5-104 (IEC 104) protocol is one of the most important standards for modern SCADA and telecontrol systems.

It extends the earlier IEC 60870-5-101 serial protocol by enabling communication over Ethernet and TCP/IP networks, allowing utilities and industries to operate over LAN, WAN, or even public IP networks with reliability and scalability.

This article explains — in plain yet technical language — how IEC 104 works over Ethernet, what makes it different from older serial communication methods, and how data is transmitted securely between control centers and field devices.

Table of Contents

From IEC 101 to IEC 104 — The Evolution to Ethernet

Originally, IEC 60870-5-101 was designed for serial lines (RS-232/RS-485) and low-bandwidth links like radio or leased lines.

However, as networks evolved, SCADA systems required higher speed and easier integration with IT infrastructure.

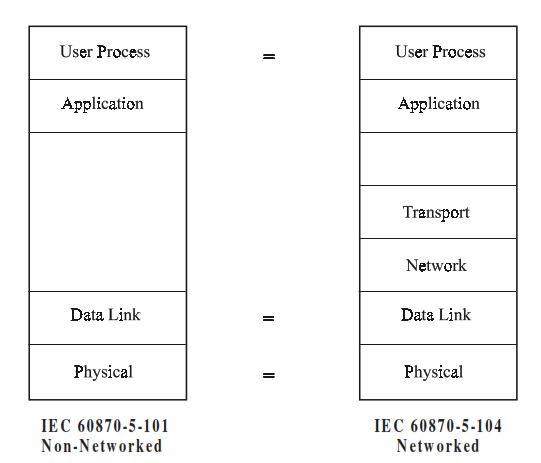

IEC 104 was introduced as a companion standard to IEC 101, keeping the same application layer (ASDU structure, command types, etc.) but replacing the lower layers with standard TCP/IP and Ethernet transport.

| Standard | Physical Layer | Link Layer | Transport |

|---|---|---|---|

| IEC 60870-5-101 | Serial (RS-232/485) | FT1.2 (custom) | None (direct) |

| IEC 60870-5-104 | Ethernet | TCP/IP | Standard Internet Protocol Stack |

IEC 104 Communication Stack Over Ethernet

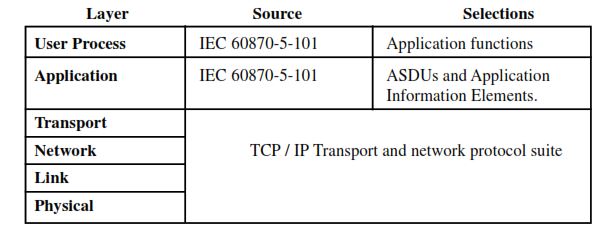

IEC 104 maps its protocol stack directly onto the OSI model, using standard network components:

| OSI Layer | Protocol Used in IEC 104 | Function |

|---|---|---|

| Application | IEC 60870-5-104 ASDU | Data objects, commands, status info |

| Transport | TCP (RFC 793) | Reliable, ordered data delivery |

| Network | IP (RFC 791) | Routing between networks |

| Data Link | Ethernet (IEEE 802.3) | Physical media transmission |

| Physical | Copper/Fiber/Wireless | Physical connection medium |

Data Transmission — APDU, APCI, and ASDU

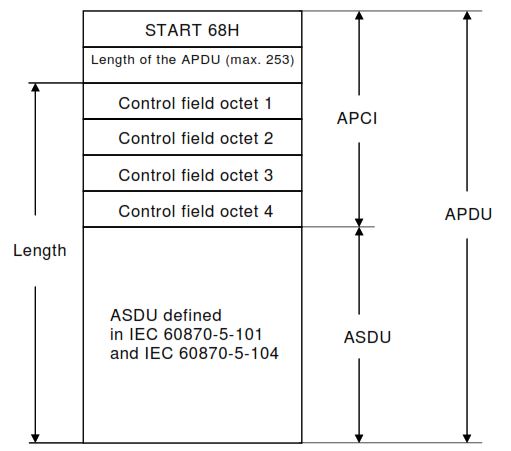

IEC 104 data travels inside Application Protocol Data Units (APDUs), which contain:

- APCI (Application Protocol Control Information) — 4 bytes of control header.

- ASDU (Application Service Data Unit) — the actual telemetry data (process values, commands, timestamps, etc.).

Example Structure:

| Field | Description |

|---|---|

| Start (0x68) | Fixed start byte |

| Length | Number of following bytes |

| Control Field | 4 bytes — sequence numbers, frame type |

| ASDU | Data object (Type ID, Cause of Transmission, Address, IOA, etc.) |

APDUs are transmitted as TCP segments within Ethernet frames, ensuring reliable and ordered delivery.

Frame Flow Over Ethernet

A typical IEC 104 message exchange over Ethernet:

- TCP Connection Establishment

- The controlling station (master) initiates a TCP session to port 2404 of the controlled station (slave).

- Acknowledged via the standard TCP 3-way handshake.

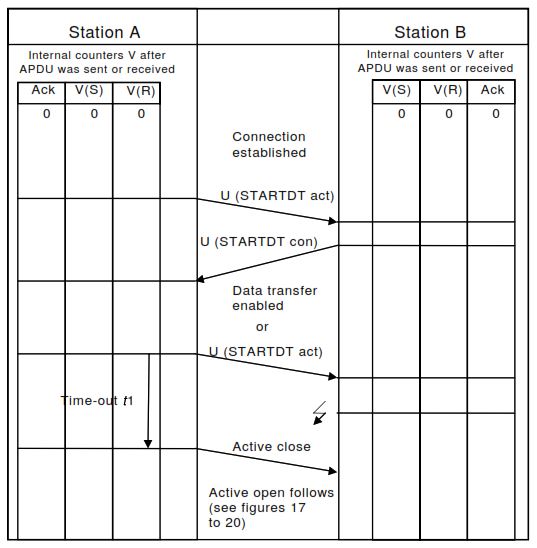

- IEC 104 Session Initialization

- Master sends Start Data Transfer (U-frame) →

STARTDT ACT - Slave responds with

STARTDT CON

- Master sends Start Data Transfer (U-frame) →

- Data Transmission

- I-format frames carry ASDU payloads.

- S-format frames acknowledge receipt.

- U-format frames handle control (Start/Stop/Test).

- Keep-Alive & Supervision

- Timers t1–t3 supervise communication.

- Idle connections send

TESTFR ACT/CONmessages.

- Disconnection

- Session ends with TCP FIN/ACK or timeout (t1 or t3 expiry).

Example: IEC 104 Over Ethernet in a Power Substation

Scenario

A utility SCADA master communicates with 10 RTUs distributed across substations over fiber Ethernet.

Flow

- Each RTU listens on TCP port 2404.

- The master opens simultaneous TCP connections.

- Real-time analog and binary data (ASDUs) are sent every few seconds.

- Events are timestamped using CP56Time2a and delivered immediately.

- Supervisory messages maintain connection health (t0–t3 timers).

This Ethernet-based approach supports millisecond-level data updates, redundant links, and diagnostic visibility using common IT tools (ping, Wireshark, SNMP).

Security and Reliability Over Ethernet

While Ethernet and TCP/IP improve performance, they also expose IEC 104 to cyber threats.

Therefore, secure deployment requires:

- Network segmentation — isolate SCADA VLANs.

- Encryption (IEC 62351-5 or TLS-104) — secure IEC 104 sessions.

- Firewall rules — restrict traffic to TCP port 2404 only.

- Monitoring — use DPI or protocol analyzers for anomaly detection.

Adopting a Zero-Trust Architecture ensures that no device or network segment is automatically trusted — every IEC 104 session is verified and logged.

🧩 Read next: Zero-Trust Architecture for SCADA »

Monitoring and Diagnostics

Wireshark is the most common tool to inspect IEC 104 traffic over Ethernet.

Filter examples:

tcp.port == 2404→ All IEC 104 trafficiec104.asdu.typeid == 45→ Single-point informationiec104.apci.type == 3→ U-format control frames

Engineers can analyze:

- Sequence numbers

- ASDU type IDs

- Response times

- Missed acknowledgments (for tuning t1–t3 timers)

Advantages of IEC 104 Over Ethernet

- High speed — faster polling and response time

- Network flexibility — works over LAN, WAN, fiber, or VPN

- Interoperability — standardized TCP/IP implementation

- Scalability — supports hundreds of simultaneous RTU connections

- Easy monitoring — uses standard network diagnostic tools

- Future-ready — integrates easily with IEC 62351, 61850, and DNP3/IP

Next Step: Decode Real IEC 104 Ethernet Frames

Want to see how IEC 104 looks on the wire?

Use the IEC 60870-5-104 Frame Decoder to visualize APCI headers, ASDU data, and timestamps (CP56Time2a) from real Ethernet captures.