The CIP protocol (Common Industrial Protocol) is an open, object-oriented communication standard used across modern industrial automation. It defines how devices organize data, how services are requested, and how real-time I/O and safety/motion extensions operate—while running over multiple network types such as EtherNet/IP, DeviceNet, ControlNet, and CompoNet. This guide explains CIP’s architecture, object model, messaging, connections, safety and motion features, and practical use in simple technical language.

Unlike basic fieldbus protocols that only describe low-level data exchange, the CIP protocol defines a complete application model, including:

- Standardized objects

- Standardized attributes

- Standardized services

- A predictable addressing model

- A real-time messaging structure

- Standardized device profiles

- Multi-network routing

- Extensions for safety, motion, and synchronization

Because of its design, CIP has become one of the most common and powerful protocols in modern industrial automation architectures.

Table of Contents

1. Why CIP Protocol Was Created

Before protocols like the CIP protocol existed, industrial environments were filled with multiple, incompatible networks. One network handled control, another handled safety, another handled information, and none spoke the same language.

This lack of interoperability caused:

- High engineering cost

- Complex maintenance

- Difficult diagnostics

- Vendor lock-in

- Inefficient data sharing

CIP was created to solve these problems by offering:

- A unified, open application layer for industrial communication

- A consistent data model across all devices

- Multi-vendor interoperability

- The ability to run over multiple physical network types

This makes the CIP protocol one of the most flexible and scalable industrial protocols available today.

2. CIP Protocol Architecture and Object Model

The architecture of the CIP protocol (Common Industrial Protocol) is built on two fundamental pillars:

- A layered communication and network architecture

- A standardized object model that defines how every device organizes data

Together, these two components allow CIP devices—from simple sensors to complex motion controllers—to communicate consistently across EtherNet/IP, CompoNet, ControlNet, and DeviceNet.

2.1 CIP Architecture Overview

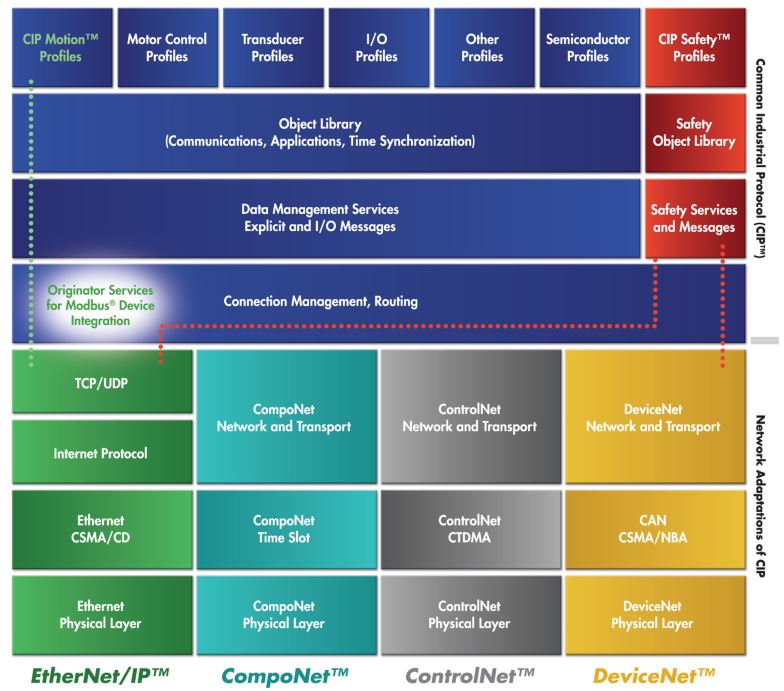

The CIP protocol is structured as a layered model. At the top, CIP defines many device profiles, including motion, I/O, transducers, motor control, semiconductor, and safety profiles. These profiles ensure that devices perform consistently across different vendors and applications.

Below the profiles sits the Object Library, which contains all standardized communication, application, timing, safety, and synchronization objects. This is followed by data management services, which include:

- Explicit messaging for configuration and diagnostics

- Implicit (I/O) messaging for real-time control

Under these layers, connection management and routing define how devices establish communication paths, set update rates, exchange cyclic data, and send messages across multiple CIP networks.

At the bottom of the architecture are the network adaptation layers, which describe how CIP maps onto different physical networks:

- EtherNet/IP → Ethernet, TCP/UDP, IP

- CompoNet → High-speed time-slot mechanism

- ControlNet → Deterministic CTDMA

- DeviceNet → CAN-based messaging

This design allows the same CIP application layer to run uniformly across four very different network technologies, ensuring interoperability and scalability throughout industrial systems.

2.2 CIP Object Model

The CIP protocol is built around a standard object model. Every CIP device exposes its internal features through a structured set of objects, allowing PLCs, drives, tools, robots, and sensors to interact with them in a predictable and uniform way.

2.2.1 Objects, Classes, Instances, and Attributes

Every CIP object contains four key elements:

- Class — defines the type of object

- Instances — individual occurrences of that class

- Attributes — data values stored in the object

- Services — actions that can be performed on the object

This structure applies consistently across all CIP devices, regardless of device type or manufacturer.

2.2.2 What Objects Represent

Objects are used to represent almost everything inside a CIP device, including:

- Identity information

(vendor ID, product type, revision, serial number) - I/O data

(input assemblies, output assemblies) - Device parameters

(configuration settings, operating modes) - Network interfaces

(Ethernet link, TCP/IP interface, DeviceNet interface) - Connections

(I/O connections, explicit messaging connections) - Motion axes

(feedback, command, synchronization objects) - Safety channels

(safe inputs, safe outputs, validator/supervisor objects)

2.2.3 Object Addressing

The CIP addressing structure is simple and universal:

Class → Instance → AttributeExample:

Class 0x01 → Instance 1 → Attribute 4This addressing method makes CIP objects easy to access, automate, and configure, both manually and programmatically.

3. CIP Services

Services define what actions can be performed on objects.

Common services include:

Get_Attribute_SingleSet_Attribute_SingleGet_Attributes_AllResetForward_OpenForward_Close

Services allow configuration tools, PLCs, robots, drives, and safety controllers to read and write attributes, initiate commands, and manage communication connections.

4. Messaging in the CIP Protocol

CIP communications fall into two major categories: explicit messaging and implicit messaging.

4.1 Explicit Messaging

Explicit messaging is used for:

- Configuration

- Diagnostics

- Parameter access

- Device management

- Status checks

- Programmatic queries

Characteristics:

- Request/response format

- Includes the object path and service code

- Not time-critical

- Typically uses TCP/IP (in EtherNet/IP systems)

Example:

“Read attribute 2 from instance 1 of class 0x01.”4.2 Implicit Messaging (I/O Messaging)

Implicit messaging is used for real-time data such as:

- Sensor values

- Drive commands

- Motion feedback

- Safety signals

- High-speed I/O updates

Characteristics:

- No embedded service codes

- Uses connection IDs instead of explicit addressing

- Very efficient

- Can be multicast

- Often uses UDP (in EtherNet/IP systems)

Implicit messaging is the backbone of real-time industrial control using the CIP protocol.

5. CIP Connections

CIP is a connection-based protocol.

Before exchanging real-time I/O, devices establish a connection using the Forward_Open service.

A CIP connection defines:

- Direction: producer → consumer

- Connection trigger: cyclic, change-of-state, event

- Update rate (RPI)

- Timeout multiplier

- Unicast or multicast behavior

- Message size

- Application path (assembly objects or other objects)

Types of CIP Connections

- I/O Connections (implicit messaging)

- Explicit Messaging Connections (explicit requests/responses)

Multiple CIP connections may be active at once, each with its own independent timing and data mapping.

6. The Producer/Consumer Model

The CIP protocol uses a producer/consumer architecture instead of traditional source/destination addressing.

Benefits include:

- More efficient network bandwidth

- One message can feed many devices

- Less traffic on the network

- Lower latency for real-time control

Example:

A single drive can produce a speed feedback multicast packet, and multiple controllers can consume it simultaneously.

This model is one of the reasons EtherNet/IP, DeviceNet, ControlNet, and other CIP-based networks scale so effectively.

7. CIP Networks (Physical Transport Layers)

The CIP protocol itself is media independent, meaning the same application-level protocol can run over different physical network layers.

The four official CIP networks are:

7.1 EtherNet/IP

EtherNet/IP adapts the CIP protocol to standard Ethernet technologies.

It uses:

- TCP/IP for explicit messaging

- UDP/IP for implicit messaging

- Standard IEEE 802.3 Ethernet physical layers

EtherNet/IP supports:

- Star, ring, and linear topologies

- Device Level Ring (DLR) for fast recovery

- High-speed multicast I/O

- Motion control

- Safety control

- Time synchronization

It is today one of the world’s most widely used industrial Ethernet protocols because it is simple, scalable, and supports both real-time I/O and enterprise connectivity.

7.2 DeviceNet

DeviceNet adapts the CIP protocol to the CAN bus, offering:

- Low installation cost

- Built-in device power (24 VDC)

- Short deterministic update cycles

- Trunk-line / drop-line wiring

DeviceNet is ideal for:

- Proximity sensors

- Simple valves

- Light stacks

- Simple I/O devices

- Small networked machine modules

It remains widely used in compact machines and industrial subsystems.

7.3 ControlNet

ControlNet adapts CIP for high-speed, deterministic control using TDMA scheduling.

It provides:

- Predictable update times

- High-speed communication

- Redundant network options

- Coordinated control across multiple devices

ControlNet is still used where deterministic timing is critical.

7.4 CompoNet

CompoNet is optimized for:

- Very small data packets

- Very fast update rates

- Large numbers of tiny I/O devices

Typical applications:

- Packaging machines

- Small pick-and-place systems

- Assembly line devices

It offers an extremely fast and efficient method for connecting simple devices on a production line.

8. CIP Object Library and Device Profiles

The CIP protocol defines a large library of standard objects that represent general functions, application functions, and network-level functions.

Examples:

General Objects

- Identity Object (0x01)

- Message Router (0x02)

- Assembly Object (0x04)

- Connection Object (0x05)

- Parameter Object (0x0F)

Application Objects

- Analog Input / Output objects

- Discrete Input / Output objects

- Presence Sensing

- Motor Data

- Motion Axis

- Event Log

- Power and Energy Management

- Safety-related objects

Network Objects

- Ethernet Link

- TCP/IP Interface

- DeviceNet Interface

- ControlNet Interface

- Redundancy objects

- QoS and SNMP objects

Device Profiles

Device profiles standardize how entire classes of devices behave. Examples include:

- AC drives

- Motion drives

- Encoders

- PLCs

- HMIs

- Vacuum controllers

- Safety I/O devices

- Motor overloads

- Contactors

- Proximity sensors

- Photoelectric sensors

Profiles specify:

- Required objects

- Optional objects

- Standard I/O assemblies

- Device behavior rules

Profiles ensure interoperability between devices from different manufacturers.

9. Assembly Objects and I/O Mapping

The Assembly Object is one of the most important in the CIP protocol. It allows:

- Grouping data from multiple objects

- Creating input and output data blocks

- Defining configuration blocks

- Allowing cyclic I/O updates

Types of Assemblies

- Input assembly → data produced by the device

- Output assembly → data consumed by the device

- Configuration assembly → data used to configure the device

Assembly objects make I/O communication far more efficient by consolidating data into predictable formats.

10. Electronic Data Sheets (EDS Files)

An Electronic Data Sheet (EDS) is a simple text file that describes:

- Identity

- I/O assemblies

- Communication options

- Parameters

- Grouping

- Supported connections

- Display formatting

- Scaling

- Units

- And more

EDS files allow configuration tools to:

- Discover device capabilities

- Display parameters meaningfully

- Download configuration

- Validate assemblies

- Configure devices offline

EDS files eliminate the need for bulky parameter objects in many small devices and make integration much easier.

11. CIP Routing Across Multiple Networks

One of the CIP protocol’s powerful features is seamless routing.

A device on EtherNet/IP can communicate with a device on DeviceNet or ControlNet by passing through routers using CIP-defined path segments.

Routing is performed using:

- Unconnected_Send for explicit messaging

- Forward_Open for connected messaging

Routers dynamically examine the path and forward messages accordingly—no manual pre-configuration is required.

12. CIP Data Management and Data Types

CIP supports standardized IEC 61131-3 data types, including:

- BOOL

- BYTE, WORD, DWORD

- SINT, INT, DINT

- USINT, UINT, UDINT

Data structures can include arrays, composite structures, and symbolic path references.

Logical segments provide flexible addressing for objects, instances, attributes, and member data.

13. CIP Safety

CIP Safety extends the CIP protocol to support functional safety up to SIL3 levels.

Features:

- Safety and standard data on the same network

- Black-channel communication

- Error detection (CRC, time, sequence, authentication)

- Safety supervisors and validators

- Safe state handling

Typical CIP Safety devices:

- Safety PLCs

- Safety relays

- Emergency stop units

- Light curtains

- Safety interlock switches

- Safety analog sensors

- Dual-channel I/O

CIP Safety is widely used in modern machinery because it reduces wiring, improves flexibility, and integrates seamlessly with standard control systems.

14. CIP Sync and CIP Motion

The CIP protocol includes advanced extensions for real-time synchronization and motion control.

14.1 CIP Sync

CIP Sync uses IEEE-1588 Precision Time Protocol to synchronize devices to within sub-microsecond accuracy. This gives all devices a shared notion of time, enabling coordinated and deterministic control functions.

14.2 CIP Motion

CIP Motion builds on CIP Sync and provides:

- Multi-axis coordination

- High-speed motion updates

- Accurate drive-to-drive synchronization

- Integrated motion + standard I/O on the same network

- Support for complex motion profiles

Typical applications:

- Robotics

- Packaging machinery

- Servo-axis coordination

- High-speed assembly systems

CIP Motion allows a single EtherNet/IP network to handle both standard control and advanced motion control, simplifying machine design.

15. Real-World Example: A PLC Communicating with a CIP Device

Imagine a PLC interacting with a smart I/O block or a servo drive using the CIP protocol.

Step 1 — Forward_Open

The PLC sends a Forward_Open request specifying:

- Input assembly instance

- Output assembly instance

- RPI (update rate)

- Trigger method

- Timeout settings

Step 2 — Connection Established

The device allocates resources for the connection and prepares data structures.

Step 3 — Implicit Messaging Starts

At each RPI (e.g., every 10 ms), the device:

- Produces input data

- Consumes output data

The PLC updates its internal I/O tables accordingly.

Step 4 — Runtime Behavior

The PLC logic processes the data in real time:

- Inputs → used for decisions

- Outputs → sent to actuators or drives

Step 5 — Forward_Close

When the system no longer requires the connection, the PLC closes it to free resources.

16. Benefits of the CIP Protocol

✔ Interoperability

Vendors follow common object models and profiles.

✔ Scalability

Works for small sensors and huge distributed systems.

✔ Real-time performance

Implicit messaging and multicast enable extremely fast I/O.

✔ Vendor-neutral architecture

Standardized objects and services ensure predictable behavior.

✔ Rich feature set

Safety, motion, time sync, energy management, configuration, diagnostics.

✔ Multi-network operation

Same protocol runs on 4 different industrial networks.

✔ Seamless routing

CIP-routing lets messages travel across different networks without special configuration.

17. CIP vs Other Industrial Protocols

CIP vs PROFINET

| Feature | CIP Protocol | PROFINET |

|---|---|---|

| Object model | Strong | Moderate |

| Safety | CIP Safety | PROFIsafe |

| Motion | CIP Motion | PROFINET IRT |

| Network independence | Yes | No (Ethernet only) |

| Multicast efficiency | High | Moderate |

CIP vs EtherCAT

| Feature | CIP Protocol | EtherCAT |

|---|---|---|

| Latency | Millisecond | Microsecond |

| Architecture | Programmable & flexible | Hard real-time |

| Object model | Full | Limited (CoE dictionary) |

| Motion | Integrated | Very high performance |

CIP is generally more flexible, while EtherCAT excels in raw speed.

18. The Future of the CIP Protocol

CIP development continues to evolve with:

- Industry 4.0

- Industrial IoT integration

- Cloud connectivity

- TSN (Time-Sensitive Networking)

- Distributed analytics

- Network redundancy improvements

- Advanced cybersecurity

CIP’s modular architecture ensures it remains relevant and adaptable for decades.

Conclusion

The CIP protocol is one of the most comprehensive and powerful communication frameworks in industry today. Its object-based architecture, rich set of services, predictable behavior, and ability to run on multiple network types make it ideal for modern manufacturing systems.

Whether you are working with PLCs, robots, drives, safety systems, sensors, motion control, or energy management devices, understanding the CIP protocol gives you a clear advantage in designing, troubleshooting, and optimizing industrial automation systems.